Abstract

Introduction:

The cause of osteolysis in a hard-on-polymer artificial joint is the discharge of fine polyethylene wear particles with micron or submicron sizes from the polyethylene that stimulates macrophage activity and promotes the secretion of cytokines. In general assay procedures, the macrophages were cultured in the presence of the UHMWPE particles in the well plates and the culture supernatants were then used for the measurement of cytokines based on the enzyme-linked immunosorbent assay (ELISA).

In this report, for a highly dense culture between the macrophages and the microscopic particles, the fabrication of the microfluidic device for secretions of inflammatory cytokines from human monocyte-derived macrophage (HMDM) is explained, and a sequence of reliability verification tests is performed.

Methods:

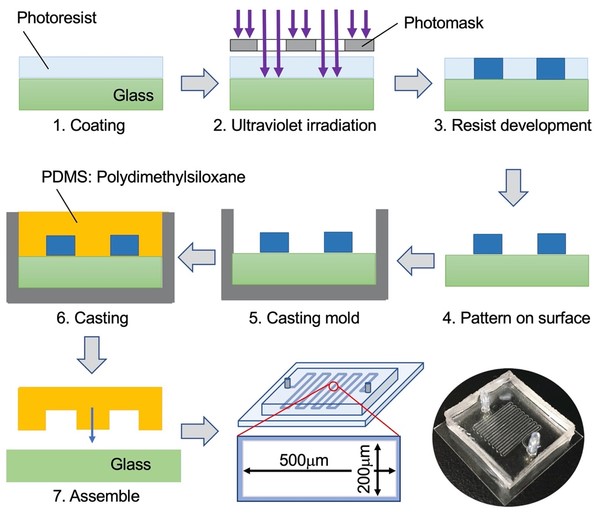

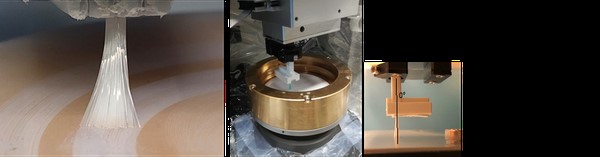

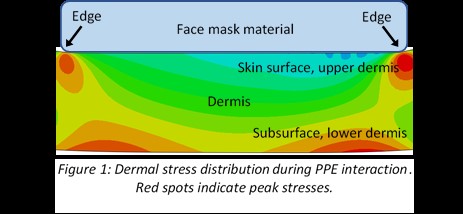

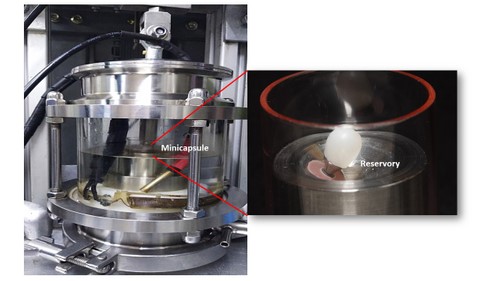

Figure 1 shows the fabrication process of the microfluidic device. The device consists of a narrow flow channel (dimensions of 200 × 500 μm), wherein a highly dense culture of human monocyte-derived macrophages (HMDM) and microscopic particles is expected to be formed. Fluorescent polystyrene particles (0.051, 0.20, 0.49, 1.1, 3.2 μm in diameter) were used as the microscopic particles in order to confirm the macrophage phagocytosis. The culture medium mixed with the microscopic particles was injected into the microfluidic device. The culture medium was collected, and an enzyme-linked immunosorbent assay (ELISA) was performed to investigate the production of pro-inflammatory cytokines by HMDMs that phagocytosed the microscopic particles. Pro-inflammatory cytokines, namely, TNF-α and IL-6, were measured with the sandwich method with ELISA kits.

Results and discussion:

Despite the smaller volume of the culture medium with microscopic particles compared with that used in a conventional well-plate, the secretions patterns of TNF-α and IL-6 were confirmed. I t was confirmed that the microfluidic device was able to provide the culture environment for the secretion of inflammatory cytokines.

Figure 1: Fabrication of microfluidic device used for the secretion of inflammatory cytokines.

Text Abstract

Introduction:

The cause of osteolysis in a hard-on-polymer artificial joint is the discharge of fine polyethylene wear particles with micron or submicron sizes from the polyethylene that stimulates macrophage activity and promotes the secretion of cytokines. In general assay procedures, the macrophages were cultured in the presence of the UHMWPE particles in the well plates and the culture supernatants were then used for the measurement of cytokines based on the enzyme-linked immunosorbent assay (ELISA).

In this report, for a highly dense culture between the macrophages and the microscopic particles, the fabrication of the microfluidic device for secretions of inflammatory cytokines from human monocyte-derived macrophage (HMDM) is explained, and a sequence of reliability verification tests is performed.

Methods:

Figure 1 shows the fabrication process of the microfluidic device. The device consists of a narrow flow channel (dimensions of 200 × 500 μm), wherein a highly dense culture of human monocyte-derived macrophages (HMDM) and microscopic particles is expected to be formed. Fluorescent polystyrene particles (0.051, 0.20, 0.49, 1.1, 3.2 μm in diameter) were used as the microscopic particles in order to confirm the macrophage phagocytosis. The culture medium mixed with the microscopic particles was injected into the microfluidic device. The culture medium was collected, and an enzyme-linked immunosorbent assay (ELISA) was performed to investigate the production of pro-inflammatory cytokines by HMDMs that phagocytosed the microscopic particles. Pro-inflammatory cytokines, namely, TNF-α and IL-6, were measured with the sandwich method with ELISA kits.

Results and discussion:

Despite the smaller volume of the culture medium with microscopic particles compared with that used in a conventional well-plate, the secretions patterns of TNF-α and IL-6 were confirmed. I t was confirmed that the microfluidic device was able to provide the culture environment for the secretion of inflammatory cytokines.