Abstract

Introduction. Dissimilar metal welds in LWRs are susceptible to degradation via IASCC. We performed irradiation-assisted stress corrosion cracking (IASCC) measurements of a 304L-508LAS weldment as part of the US DOE NEUP LWR sustainability program. The 308L weld filler material recrystallizes during the welding process, with both delta ferrite and gamma austenite forming. This mixed phase microstructure prevents hot cracking of the weld during cooling.

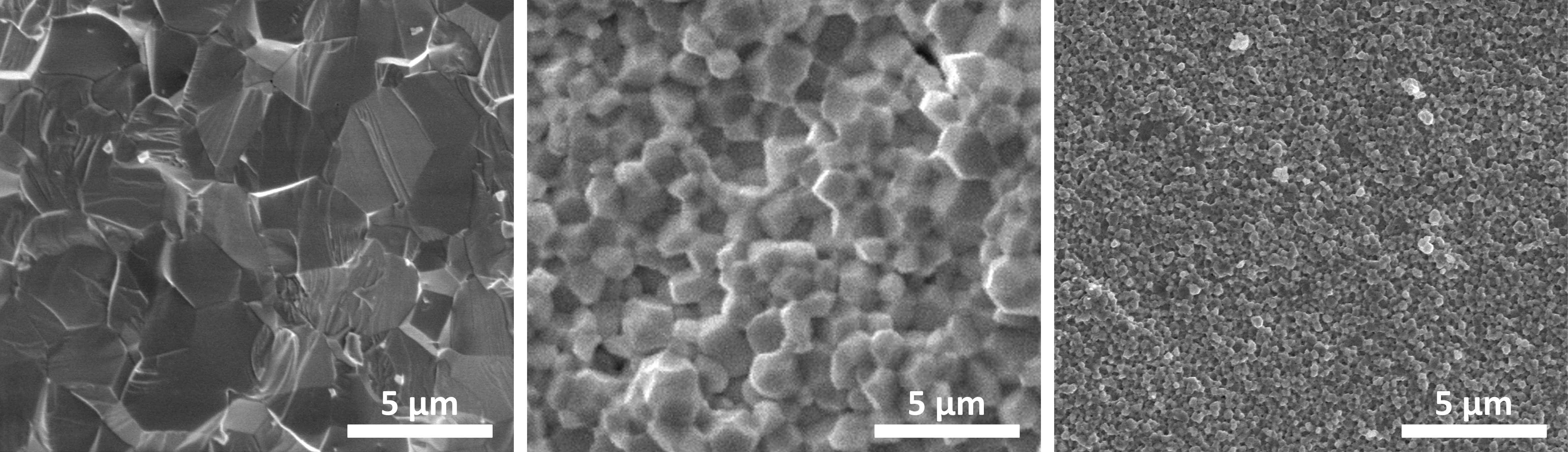

Methods. A nuclear grade 304L-308L-309L-508LAS weldment was fabricated EPRI. The 308L filler material and 309L butter material were irradiated at 360 C with 2 MeV protons to 5 dpa. SEM, TEM, and STEM-EDS were used to analyse the water facing irradiated and unirradiated surfaces after hot water immersion testing in NWC conditions (290 C, 10 MPa, 2000 ppb DO). In situ cracking was initiated by applying a tensile load to approximately 5% strain at a strain rate of 1x10-7 1/s. Lift outs were fabricating using a FEI Helios 600I dual beam FIB. The STEM-EDS images were obtained using a FEI Themis Z electron microscope.

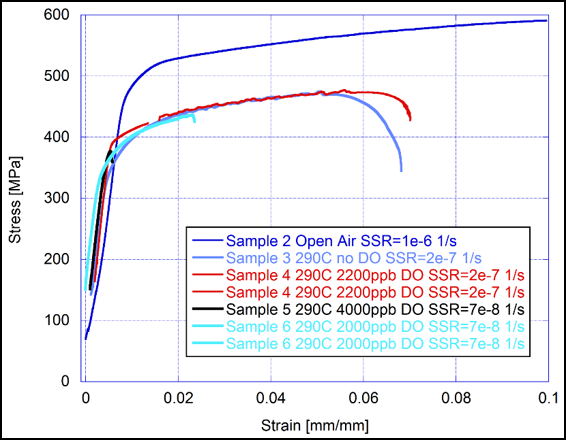

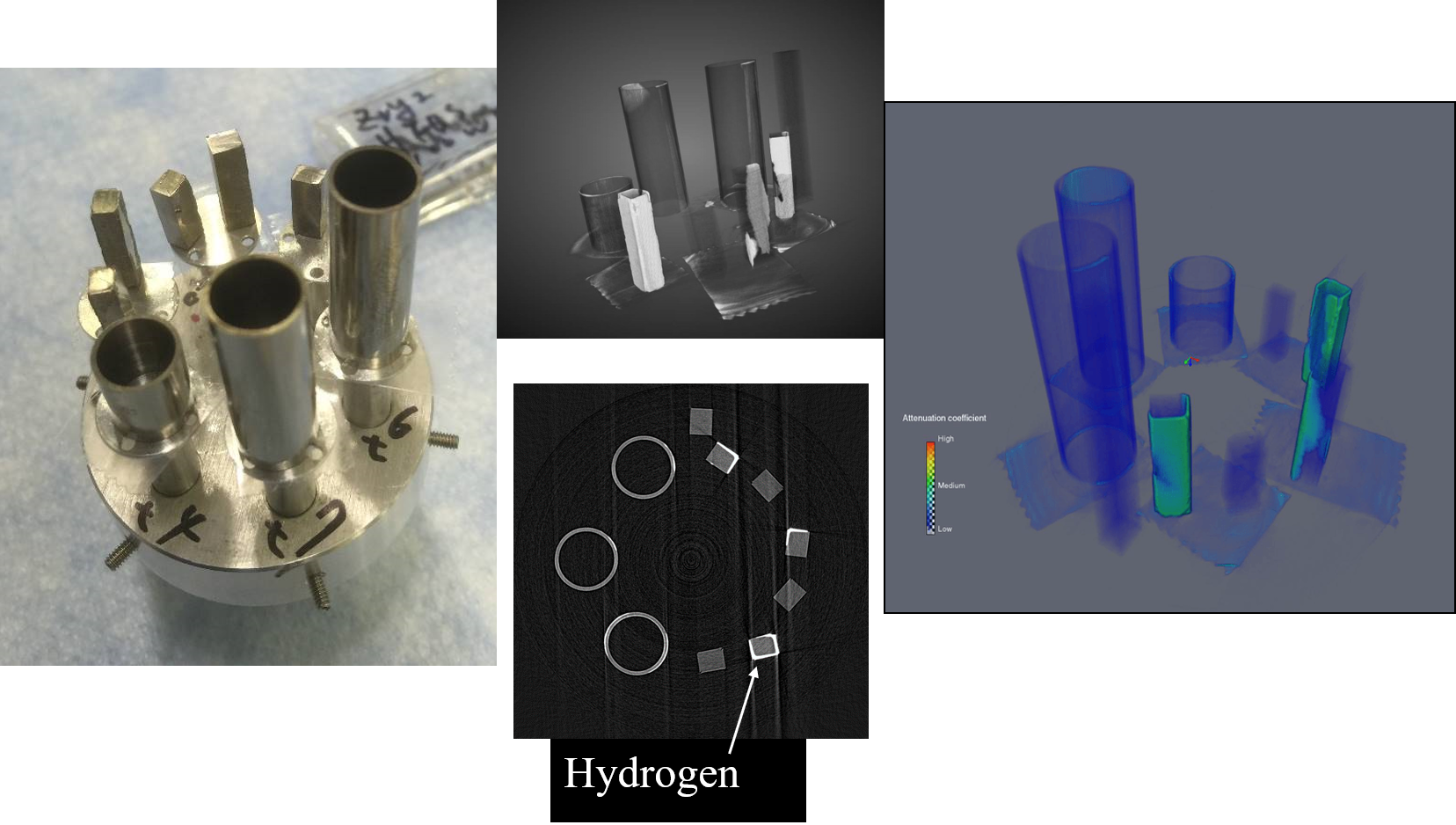

Results and discussion. Tensile engineering stress-strain curves for unirradiated specimens that spanned the entire weldment are shown in the first figure for different environmental factors, including Samples 4 and 6 in NWC (2000 ppb DO). A 3X reduction in strain rate (Sample 4 to 6) induced failure at significantly lower total strain due to longer environmental exposure. Proton irradiation induced significant cracking under the environmental conditions specified in the Methods section compared to unirradiated material from the same specimen. A STEM image of a FIB lift out at a crack in irradiated 308L filler material orthogonal to the free surface is shown in the second figure. Localized deformation channels are evident in the STEM image. The elemental map (second figure inset) indicates changes in composition that correlate to localized slip.