Abstract

Membrane bioreactors (MBRs) are successfully being adopted in super-large-scale (>100,000m3/d) wastewater treatment plants (WWTP), even if loss of membrane permeability caused by fouling induces high operational costs, mainly due to aeration, chemical cleaning and excessive recirculation (Krzeminski, 2017). Modelling offers the opportunity to reduce these costs. Activated sludge models (ASMs) have been tested on large-scale MBR plants (>10,000m3/d) (Gabarrón, 2015, Sun, 2016). However, the integrated modelling of super-large-scale MBR-WWTP including complex interactions between biology, filtration, and fouling has not been done yet.

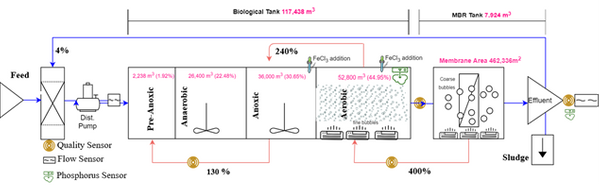

A super-large-scale MBR plant (Figure, 360,000m3/day) characterised by hollow fibre membranes (PVDF with pore size 0.4µm) with total surface area of 460,000m2 and receiving wastewater from Paris region has been considered for modelling. Online operational and flow quality data were collected for three months. Furthermore, COD fractions, autotrophs (XANO), and heterotrophs (XOHO) concentrations and their yield coefficients were measured. After cleaning and validation, these data were used to initialise and validate the simulations. A dynamic integrated model involving the coupling of EPS-ASM3-BioP and filtration models (Janus 2014, Rieger et al 2001) was developed and implemented in MATLAB environment. The biological part of the model considers the stoichio-kinetic activity of the biomass for the carbon, nitrogen and phosphorus removal. The filtration model covers the biomass fouling dynamics due to intermittent air scouring. The complexity of the data treatment and its simplification for modelling were discussed. Mean relative error showed that the simulated results are close to the real data. The super-large-scale MBR modelling allows optimising its functioning in terms of depollution performance and operational costs, and it could be the base of advanced control.

References

Krzeminski, et al. 2017, JMS 527:207‑27.

Janus 2014, Procedia Engineering 70:882–891

Gabarrón et al. 2015, CEJ 267:34-42.

Rieger et al. 2001, WR 16:3887‑3903

Sun et al. 2016, WR 93:205-213.

Figure: MBR Plant Schematic