Abstract

Introduction

Zeolitic-imidazolate frameworks (ZIFs) are candidate materials for the next generation of membranes for cheaper separations. Herein, we demonstrate the effectiveness of molecular-scale modification in the design of new ZIFs useful for the separation of important mixtures such as H2/CH4, CO2/CH4.

Methods

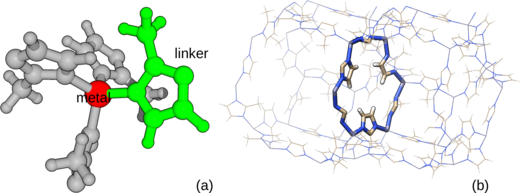

We construct new ZIFs by replacing the original metal, Zn2+, and the original organic linker, mIm, in the basic unit of ZIF-8 (Figure 1(a)), with three different metals (Be2+, Cu2+, Co2+) and one different linker (bIm), to produce ZIF-8 analogues. Unit replacement offers control over the size of the aperture that bridges the cages of the ZIF (Figure 1(b)) and subsequently control over the separation efficiency.1,2

Figure 1. (a) basic tetrahedra unit in ZIF-8 topology and (b) aperture connecting two cages.

Molecular simulations were employed to estimate the permeabilities of He, H2, CO2, N2 and CH4 and selectivities of the corresponding mixtures. Details on our simulation approach and the force fields we developed for these calculations can be found in our recent works.1,2,3

Results

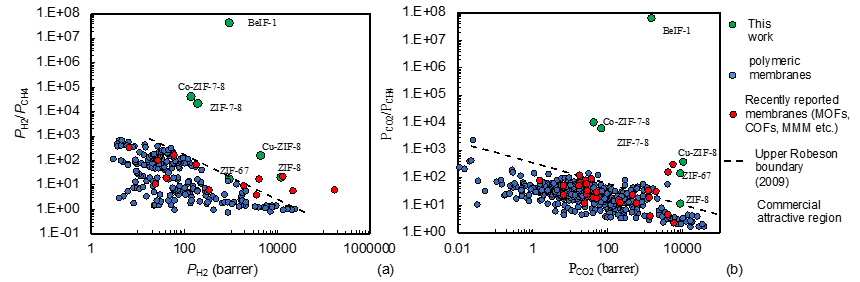

In the case of H2/CH4 the new modifications demonstrate a clearly improved performance over ZIF-8 already considerable performance, and they surpass the existing competition (Figure 2(a)). In the case CO2/CH4, the modifications offer a considerable improvement over the original ZIF-8 average separation. In both cases, BeIF-1 exhibits an outstanding performance.

Figure 2. (a) H2/CH4 and (b) CO2/ CH4: Performance of the ZIFs of this work in comparison with membrane data from literature.

Discussion

The results and the comparison with existing membranes acts as a proof of the possibility to develop membranes of unprecedent separation performance.

References

- Krokidas et al. Phys. Chem. Chem. Phys. 2018, 20 (7), 4879.

- Krokidas et al. ACS Appl. Mater. Interfaces 2018, 10 (46), 39631.

- Krokidas et al, under review.