Abstract Text

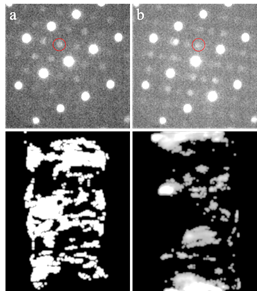

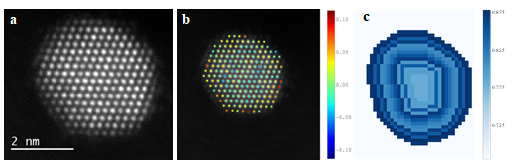

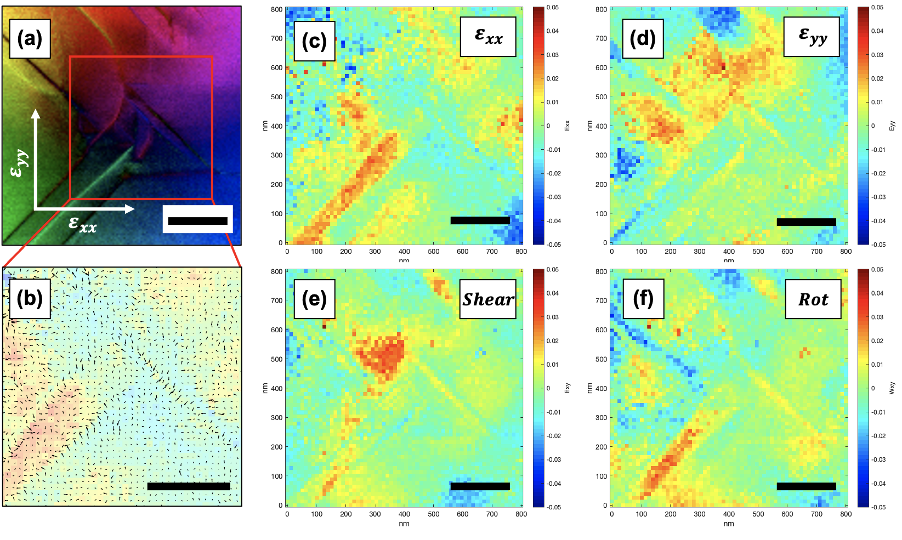

Heusler alloy of Co2FeSi (CFS) has been regarded as one of the most promising candidates for spintronics applications due to its high magnetic moment and theoretically possible full spin polarization1,2. These desired properties are heavily affected by the presence of structural ordering of phases within CFS. In this study, phase ordering of CFS full-Heusler thin films were investigated using correlated EDS and 4D-STEM approaches. Unsupervised machine learning (ML) methods including decomposition and clustering approaches3 were implemented to provide insight into the structural and solute variations within the films. Previous XRD measurements suggested B2 (Pm-3m) and L21 (Fm-3m) ordering, however, PCA and fuzzy clustering ML methods indicated an unexpected phase in addition to B2 and L21. This minority superstructure may help to explain variations in magnetocrystalline anisotropy in these films. Correlated EDS signals provide a pathway to identify the unexpected phase. Figure 1 shows PCA and fuzzy clustering outputs of a CFS thin film grown on Si(111). Figure 1-a belongs to B2/L21 phase, evident by the (200) (red circle) and (111) type reflections, and Figure 1-b belongs to the unexpected phase of this system.

Figure 1. Decomposed diffraction patterns and accompanying memberships maps of two distinct ordered phases of CFS thin film.

Cluster memberships (the lower panels) show how these phases are complementary in the films, similar studies on composition variation in the films are underway to address the possibility of local segregation of solute causing these differences in superstructure ordering.

Keywords

Heusler alloys, 4DSTEM, machine learning

References

1. Gercsi, Z. et al. Spin polarization of Co 2FeSi full-heusler alloy and tunneling magnetoresistance of its magnetic tunneling junctions. Appl. Phys. Lett. 89, 082512 (2006).

2. Zhu, W. et al. Magnetization precession and damping in Co 2 FeSi Heusler alloy thin films. J. Magn. Magn. Mater. 479, 179–184 (2019).

3. Martineau, B. H., Johnstone, D. N., van Helvoort, A. T. J., Midgley, P. A. & Eggeman, A. S. Unsupervised machine learning applied to scanning precession electron diffraction data. Adv. Struct. Chem. Imaging 5, 3 (2019).