Introduction

In steel structural system analysis some factors, such as geometric imperfections, material nonlinearity and semi-rigid connections, can contribute to the reduction of the structural system bearing capacity.

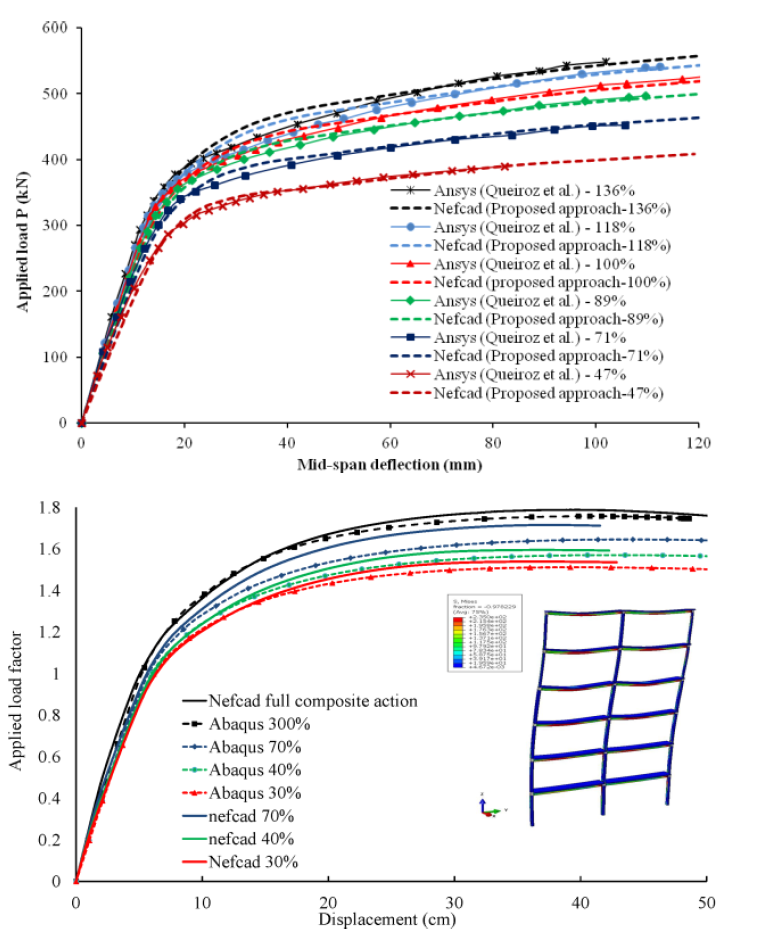

In the numerical context, there are several researches that deal with the semi-rigid joints and plastification of steel structures (Chan & Chui, 2000; Lemes et al., 2017). To describe the connections behavior, it is common to use zero-length rotational pseudo-springs at the finite elements ends. The Refined Plastic Hinge Method (RPHM) has emerged as a fast and accurate option for structural plastification simulation. Lemes et al. (2017) developed an alignment of the Strain Compatibility Method (SCM) with the RPHM producing reliable results in the analysis of steel, reinforced concrete and steel-concrete composite structures. Another important factor in the steel plasticity analysis is the residual stresses.

The objective of the present work is to promote the use of the SCM/RPHM with the pseudo-springs at the finite elements ends, representing the beam-to-column connections, in the steel structures systems modeling. Some results are illustrated for validation of the proposed methodology.

Methods

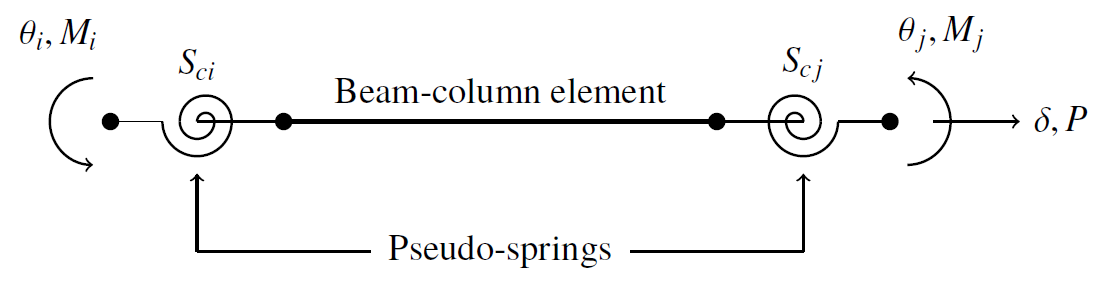

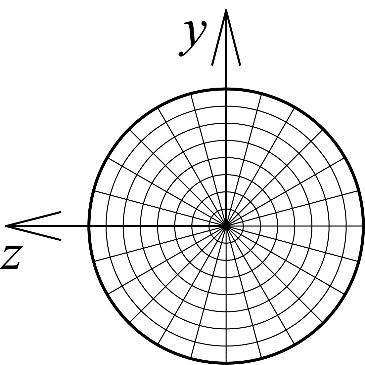

In the model of the structural systems using co-rotational-FE, the beam-column finite element is used, defined by nodes i and j, as shown in Fig. 1. The finite element equilibrium, in incremental form, is given by:

Figure 1: Co-rotational hybrid beam-column finite element

(1) |

with β = (Sci + k22) (Scj + k33) - k23 k32. ΔP, ΔMci and ΔMcj are the axial force and bending moments increments; Δδ, Δθci and Δθcj are the axial displacement and nodal rotations increments, respectively; and Sc is the spring rotational stiffness parameter. The coefficients kij of the stiffness matrix may be modified adding the geometric nonlinearity consideration, which are introduced in this methodology by the nonlinear formulation proposed by Yang and Kuo (1994).

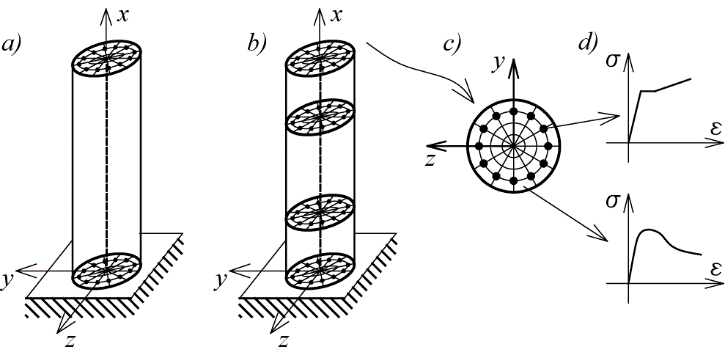

The axial and flexural stiffnesses are introduced in this formulation by the Strain Compatibility Method (SCM) (Chiorean, 2013). Thus, the moment-curvature behavior of the section is determined by the application of the standard Newton-Raphson nonlinear solution to cross sections equilibrium problem. Thus, the cross-section constitutive matrix is given by:

| (2) |

where Nint and Mint are the axial and flexural internal forces; and ε0, Φ are the axial strain and curvature of the section.

The full yield curves are obtained before the structural analysis (out of incremental cycle). This strategy is adopted to reduce the time of the numerical simulations.

When the section plastify, any increase in incremental load causes the internal forces to extrapolate the full yield curve, therefore, violating the cross-section bearing capacity. The formulation used here avoiding this violation is a strategy known as return mapping. In this strategy, the element axial force remains constant and the internal bending moment returns to the full yield curve.

Results

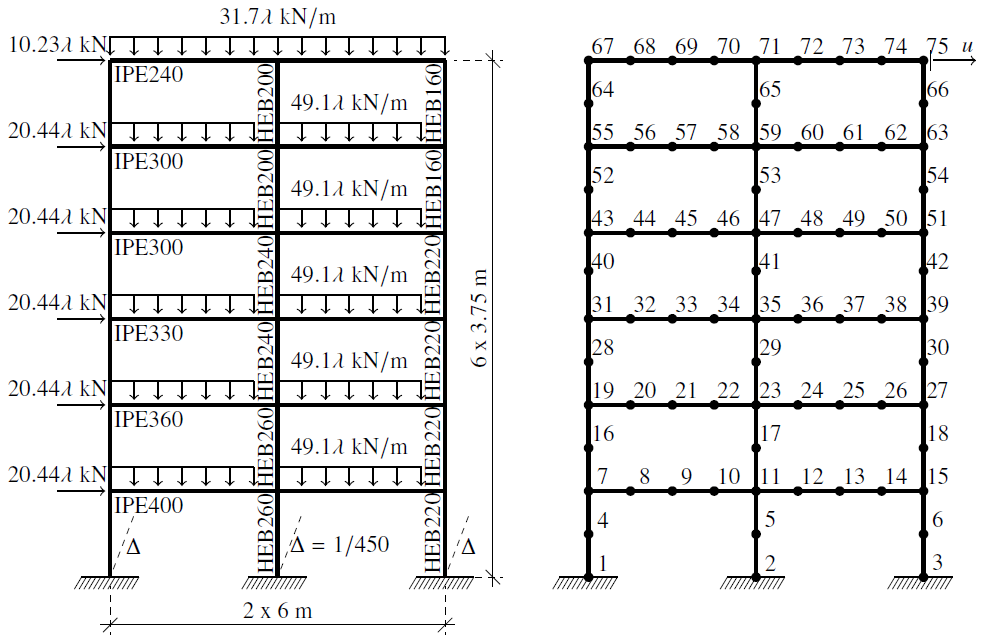

The six storey steel frame showed in Fig. 2 was initially studied by Vogel (1985) considering both distributed and concentrated plasticity. The geometry, cross-sections, loads and the used finite element mesh are represented in the same figure. All the loads are incremental. The structure has a global geometric imperfection equal to 1/450.

The steel section has yield stress equal to 235 MPa and a modulus of elasticity taken as 205 GPa. The study adopted an elastic-perfectly-plastic relationship without material strain hardening. Chan & Chui (2000) proposed a numerical study of this structural system considering the semi-rigid connections.

Figure 2: Six-storey two-bay frame: geometry, loads and adopted FE mesh

The semi-rigid connections are tested considering the linear and nonlinear behavior of the four exponential connections models described above. For simulating the joint linear behavior, the parameter Sc is kept constant and its value is taken directly from the exponential model is used (Chan & Chui, 2000). The load-displacement curves for the four analyses performed are shown in Figs. 3 and 4.

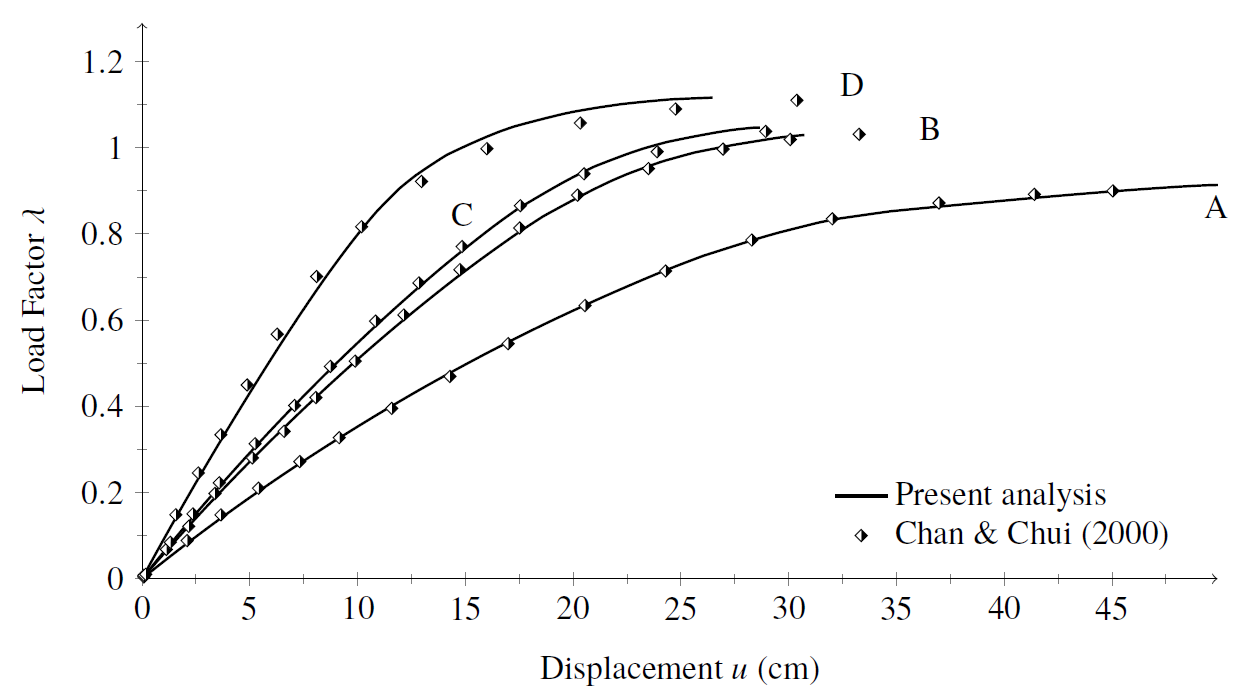

Figure 3: Vogel steel frame: equilibrium paths using linear joint model

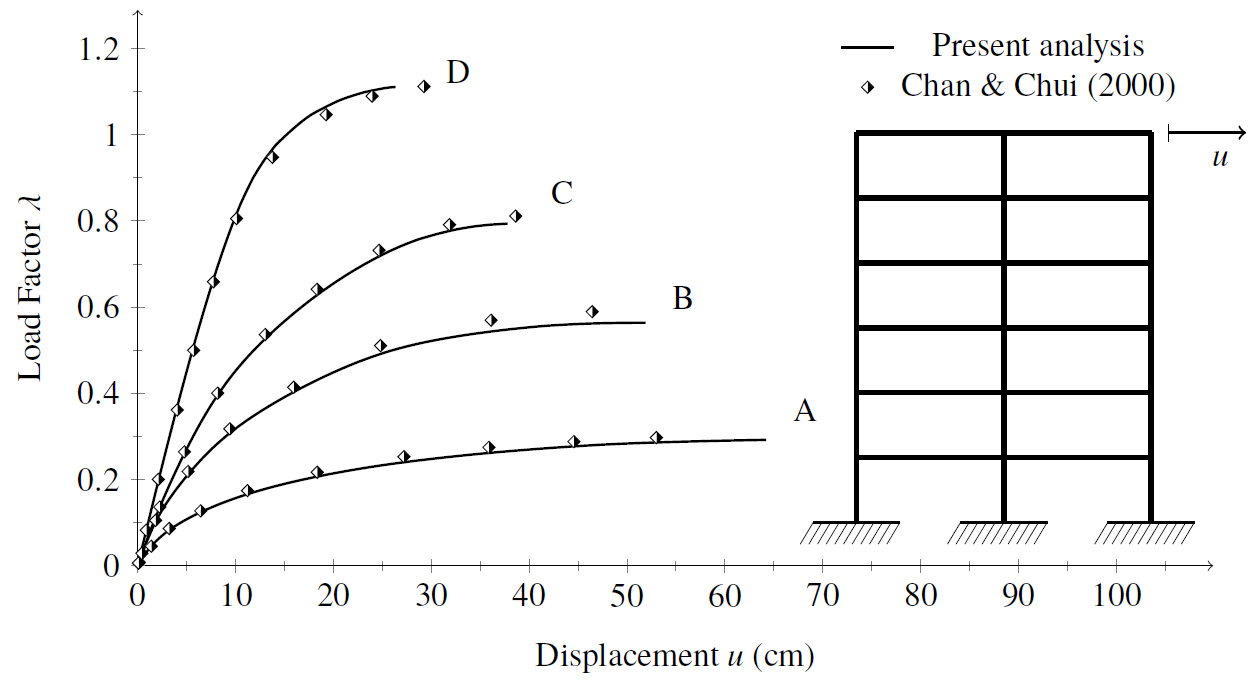

Figure 4: Vogel steel frame: equilibrium paths using nonlinear joint model

The equilibrium paths clearly demonstrate the bearing capacity variation and the structural system stiffness change as each of the four connections models are simulated. It is worth highlighting that, when adopting the nonlinear joint model, the system bearing capacity reduction using the single web angle connection (type A) is approximately 73.5% smaller than the system with extended end plate connections (type D).

In the numerical simulations with linear joint models, higher critical loads were obtained than using the nonlinear models. In fact, keeping the parameter Sc as a constant induces a more rigid system, implying smaller displacements and internal forces due to geometric nonlinearity. Moreover, when using the linear models the connection ultimate moment is not reached and the cross-section bearing capacity governs the structural system behavior.

Using the exponential model, one can clearly see a critical load reduction in a more accentuated way than using linear models for the curve M-ϕ description. Going further, one realizes that the more rigid connection, there is greater influence of the material nonlinearity. In the simulation using the D-type connection, there are 16 plastic hinges formed in addition to 43 other sections in the flexural stiffness degradation process. These numbers reduced to 1 formed plastic hinge and 39 sections degrading for analysis with type C connection. The results obtained with the semi-rigid connections B and A presented no plastic hinge formation, only partial degradation in 18 and 7 sections, respectively.

Conclusions & Contributions

This work presented a numerical formulation based on the concentrated plasticity concept and semi-rigid joints to evaluate the steel frames nonlinear behavior. For this, a hybrid finite element with rotational pseudo-springs was used. These springs were added to the finite element previously developed Lemes et al. (2017) for the simulation of the connections nonlinear behavior.

In the presented example, the good accuracy of the proposed methodology was verified when compared to the literature results. The variations in the beam-to-column connections models showed the strong influence on the global structural system behavior as well as the influence of the joint type on the inelastic behavior of the structure members. For analysis of other connection types not represented by exponential model, one can use the multilinear model for the moment-rotation relation description. In this model, the M-ϕ curve is described through a series of linear stretches that may represent any connection behavior.

Acknowledgments

The authors would like to thank CAPES, CNPq, FAPEMIG and UFOP/PROPP for the financial support received. Special thanks to Professor Péter Z. Berke from ULB for his hospitality during the manuscript’s review at Batir.

REFERENCES

CHAN, S. L.; CHUI, P. Non-linear static an cyclic analysis of steel frames with semi-rigid connections. Oxford: Elsevier, 2000.

CHIOREAN, C. G. A computer method for nonlinear inelastic analysis of 3D composite steel-concrete frame structures. Engineering Structures, v. 57, p. 125–152, 2013.

ECCS. Ultimate limit state calculation of sway frames with rigid joints. European Convention for Constructional Steelwork, Pub. no. 33, 1983.

LEMES, Í.J.M.; SILVEIRA, R.A.M.; SILVA, A.R.D.; ROCHA, P.A.S. Nonlinear analysis of two-dimensional steel, reinforced concrete and composite steel-concrete structures via coupling SCM/RPHM. Engineering Structures, v. 147, p. 12-26, 2017.

VOGEL, U. Calibrating frames. Stahlbau. Berlim, 1985.

YANG, Y.; KUO, S. Theory & analysis of nonlinear framed structures: Prentice Hall, 1994.

Abstract Summary

This work presents a numerical methodology based on Euler-Bernoulli theory to analyze the nonlinear behavior of steel planar structures. The displacement-based formulation uses the Refined Plastic Hinge Method (RPHM) principles to simulate the concentrated plasticity at the co-rotational finite element nodal points. To present a more realistic simulation of the axial and flexural stiffness degradation, the RPHM is coupled to the Strain Compatibility Method (SCM), where the materials constitutive relations are explicitly used. The SCM is also applied in determining the structural elements bearing capacity. Residual stress models are addressed and introduced explicitly in subareas of steel sections generated by a two-dimensional cross-sectional discretization. The semi-rigid connections are simulated by the rotational pseudo-springs at the finite elements ends, and the connection behavior is given by its moment-rotation relation. The presented numerical formulation results are consistent with the classical experimental and numerical literature responses